Bottle Unscrambler Machine

Main Features

The disordered bottles are carried into the sorting bottle section of the ordering bottle machine.

With the help of the pushing force of the rotating disk.The bottle enter their position.With the function of the turning bottle device and the air-flow.

The bottles are ordered into bottle mouth-up-position and are carried into next process.

With the air-transfer type conveyoring bottle system.

PLC program controlling/digit show speed.Frequency control to adjust its production capacity.

It has a screen to automatically screen out non-standard bottles.

Automatic intelligent design,the function of preventing bottle.photoelectric detection to run more smoothly.

Do not change the mould can arrange similar size different shape bottles.

Product Description

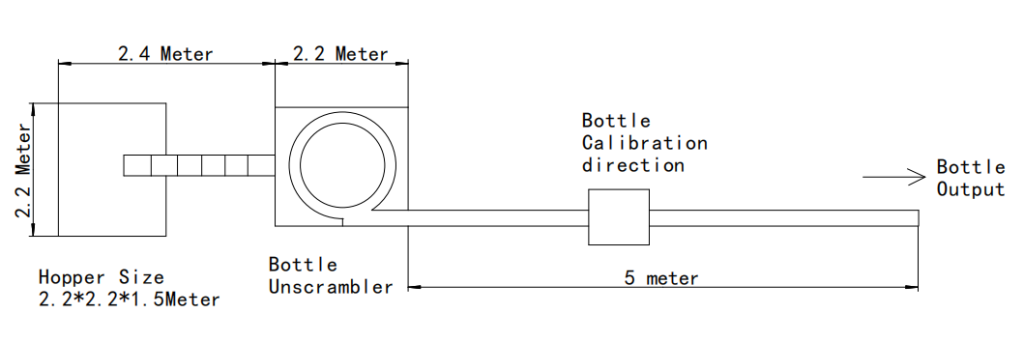

Bottle-elevator

- Consisting of Hopper, Belt and Frame.

- The elevator’s motor is controlled by the one sensor for inspecting the bottle-loading inside the unscramble.

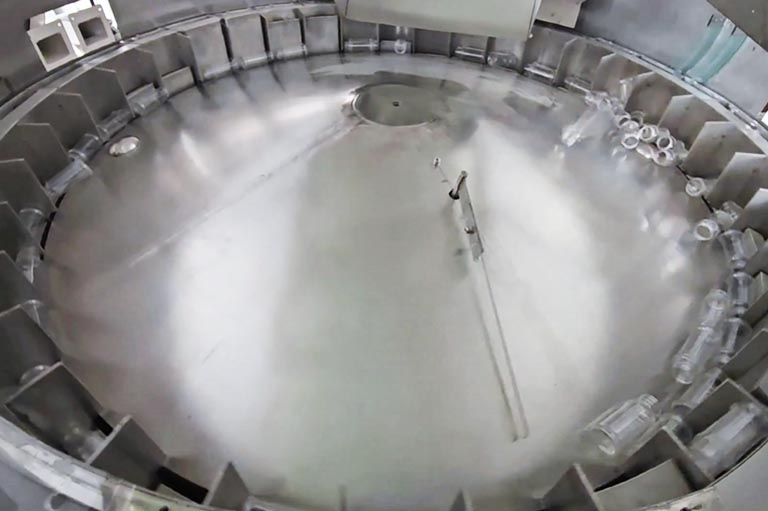

Bottle-unscrambling Part

- Consisting of main body, bottle hanger and star wheel for bottle-out.

- Its main body passes the bottles to bottle hanger, and bottle hanger inverts the bottles, and passes them to the star wheel and further to the air channel.

- Starting of Main body is automatic-controlled by checking of the bottle quantity on air channel.

In-feed star wheel

- Supply container and discharge containers smoothly on certain intervals use torque limit.

- Use of high-pressure mode-locking pressurization system, so that the bottle die line fine.

- To make machine stop when excessive force or stoppage happen on bottle in-feeding zone minimize the deviation of label adhesive.

- Change container rotation inertia into stop inertia, to ensure that even high speed bottle upside down will not appear on conveyor.

Product Paramenters

4000BPH Engine Oil 4L Bottle unscrambler

Bottle twister

- By photoelectric detection of the handle, the cylinder automatically changes direction to keep the bottle in one direction.

Get More Information About Our Products, Please Contact Us!

Factory Management

To achieve comprehensive, balanced and

rhythmic synchronous production.

Export Experience

Ensure the quality of goods and arrive within

the delivery time.

Quality Safety Reliability

Machine running test video.Customers canconfirm product quality before delivery.